National Heritage Ironwork Group

ABANA conference 2025

Historic Ironwork Weekend

Fred Suffield presentation talk

From Ruin to Revival: Conserving Our Heritage Story

As an NHIG bursary student from 2012-2013 I was asked to give a presentation on my portfolio and journey through blacksmithing and into ironwork conservation.

"She" 2012 Sculpture. Forged from 90mm round approx 6ft tall. Final degree piece for BA(Hons) Artist Blacksmithing Degree, Hereford College of Arts.

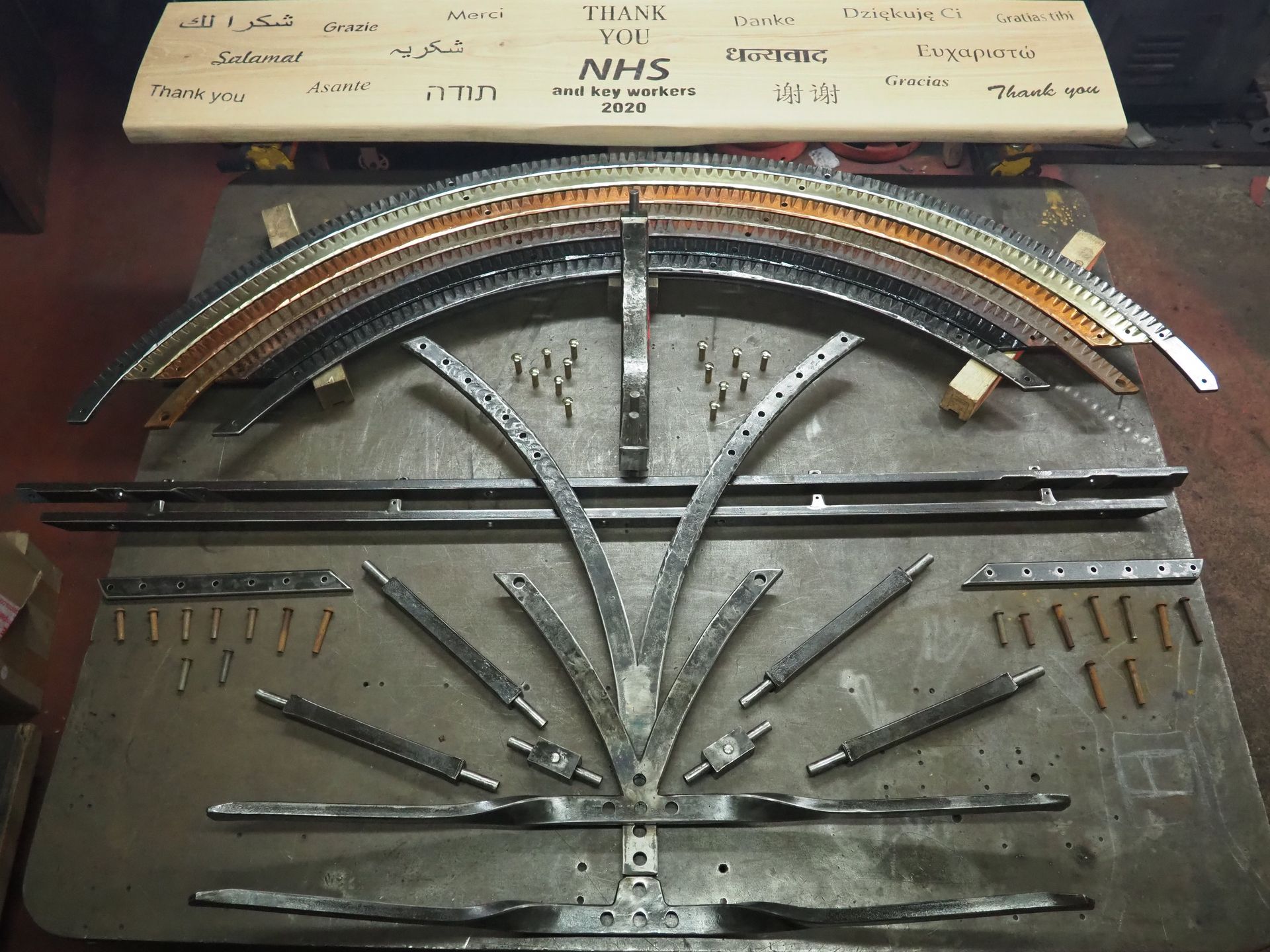

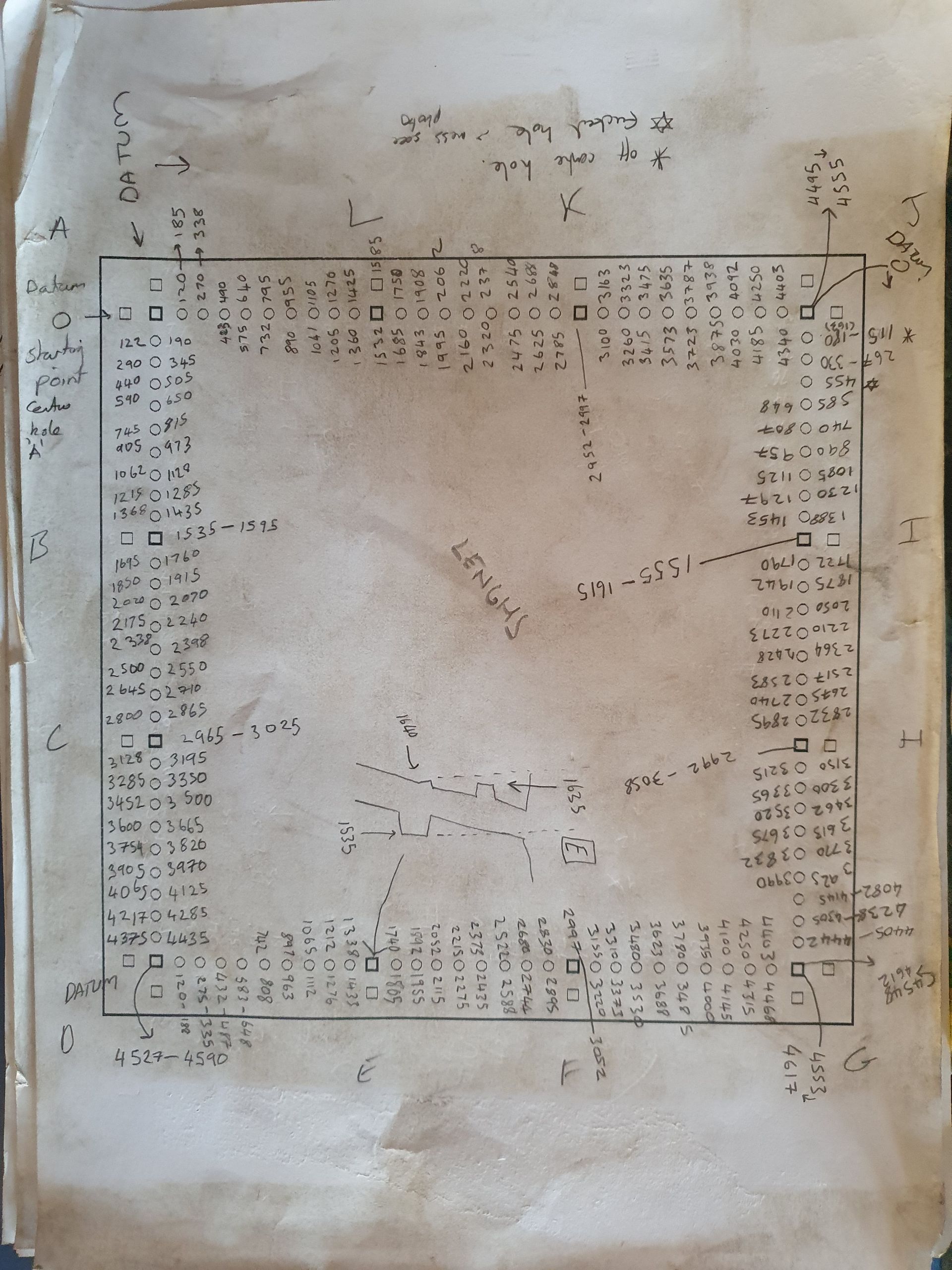

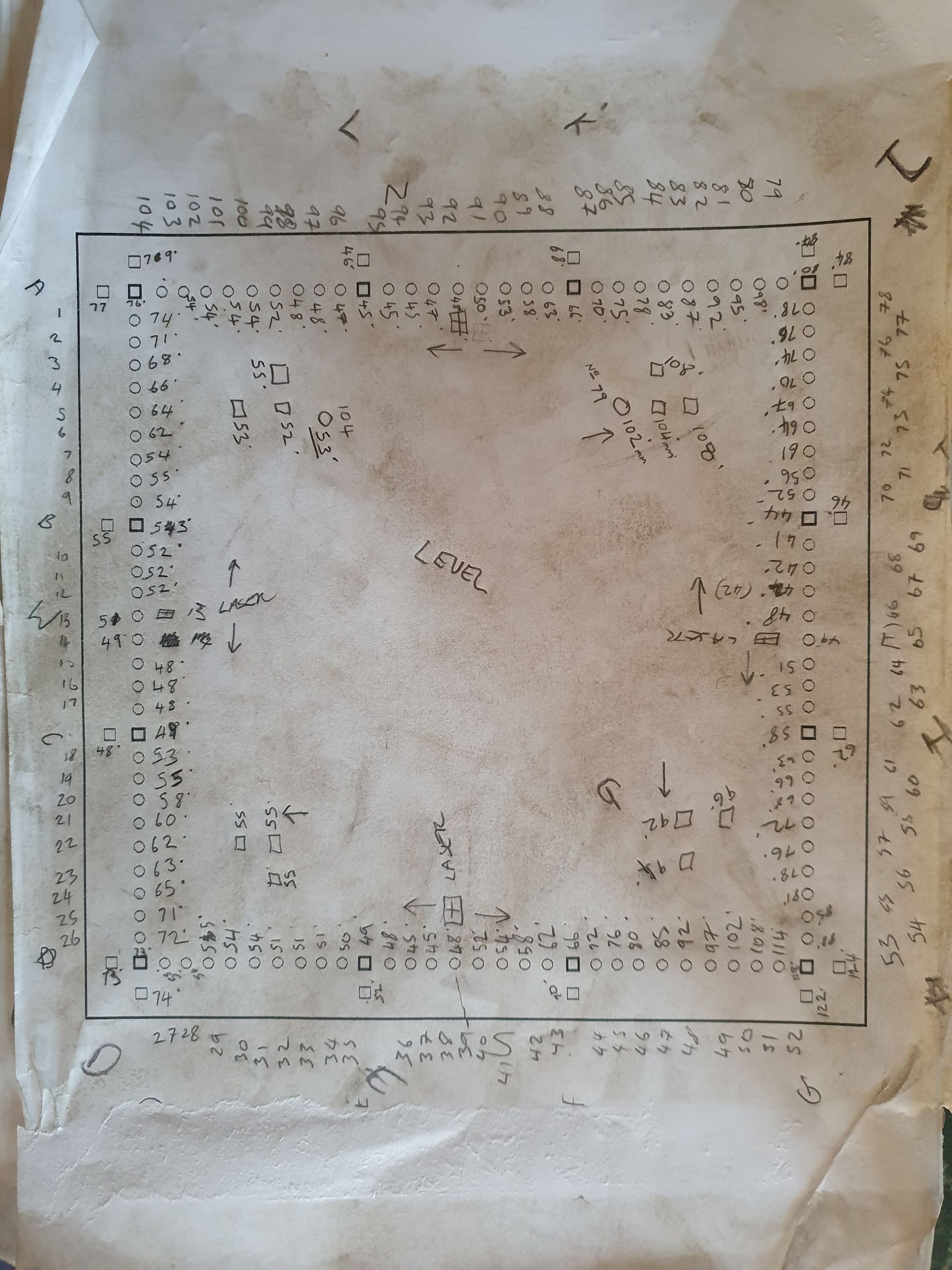

Hibaldstow Bridge. Following a misunderstanding of the term "like for like" the initial sub-contractor removed the above section of heritage wrought iron handrail sections (1/4 of the bridge) by cutting and removing with the intention to scrap. Upon our joining the project we worked with the conservation officer to establish what could be saved and conserved for fitting back to the bridge. We determined that we could save the wrought iron hand rial, the wrought iron spacers and railing frames and as much of the wrought iron lattice work as possible. We used various welding techniques to repair the cut up wrought iron, including repurposing wrought iron from elsewhere to carry out gas welding repairs. To reassemble we took laser levels from the bridge and recreated the curve within the workshop with the laid out ironwork. The new lattice work was replicated using pure iron and all ironwork was assembled loose, preparing to rivet on site. Although not ideal, we managed to save approx 90% of the historic material.

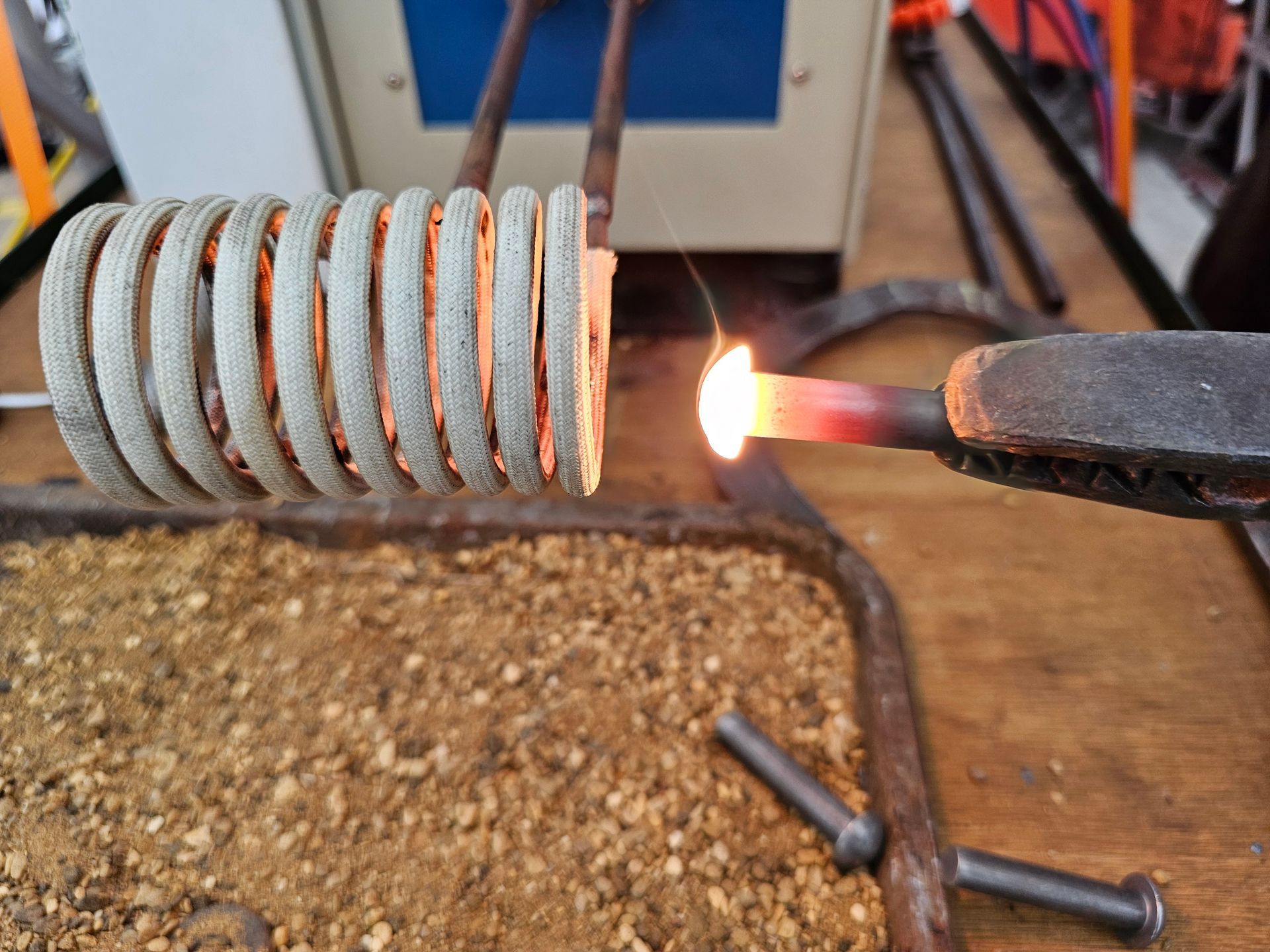

Hibaldstow Bridge. Commence riveting of all rivets in wrought iron lattice work. We made a "man-vil" back stop snap, to allow the forging of the rivets. As the latticework was light stock, we worked as a team to figure out a method for create a firm backstop without bowing the latticework. The ironwork during riveting was loosely fixed to the cast iron, to avoid excessive impact to the fragile material and to avoid any further damage or cracks.

Hibaldstow Bridge. Domed rivets on both faces of traditional overlap joint. The domed rivet snap on the "man-vil" and the matching hand snap tool allowed us to finish the rivets to the historic domed faces.

All images copyright of Anwick Forge Ltd. Please contact us if you wish to use any images or have any questions following this presentation.